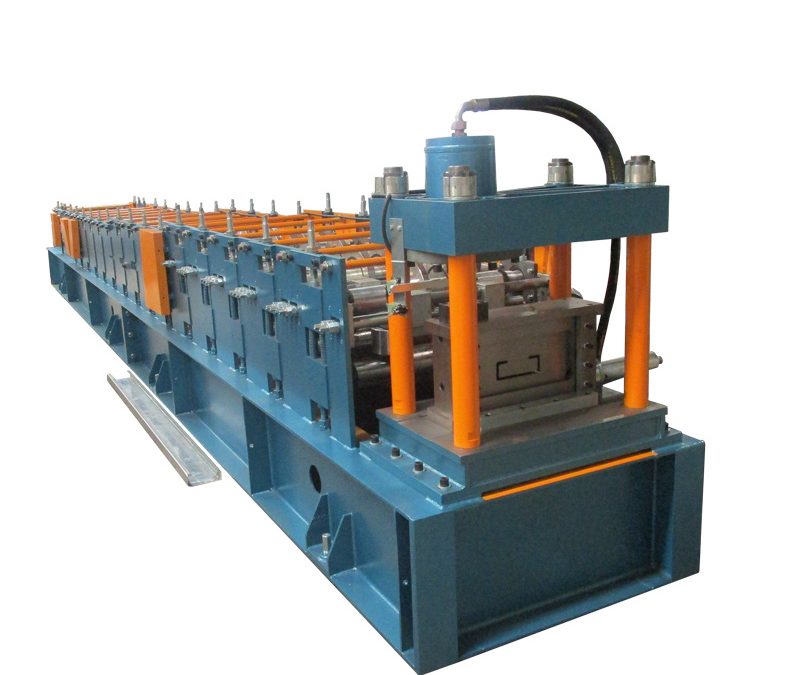

Steel CZ Purlin Roll Forming Machine Price

Steel Floor Decking Tile Roll Forming Making Machine

April 4, 2023

AUTO Cut To Length Line Machine

April 4, 2023Construction Building Machine Steel CZ Purlin Roll Forming Machine Price

Why choose this machine?

1.Certificate: ISO 9001, CE,

2. Lifetime seivices

3. Roller cover with 0.05mm chrome; 82mm diameter solid steel shaft. Lifetime>10years.

4. Introduced Mitsubishi PLC with touch screen to machine controll system.

5. One worker operation (minimum)

6. Cr12 mould steel cutter with quenched treatment. Cutting blade with heat treatment.

7. Product cut-to-length.

8.Technician overseas installing and training available

Components for the Machine

The purline forming line includes in automatic hydraulic decoiler, sheet leveling equipment, roll forming system, punching equipment, post-cutting equipment, hydraulic station, electric controlling system and supporter for purline.

Technical Parameters

| Item | Specification | |

| Material | Type | galvanized steel sheet |

| Thickness(mm) | 1.5 -3.0 | |

| Yield strength(mpa) | 235 -345 | |

| Forming speed(m/min) | About 10-12m/min | |

| Speed adjusting mode | AC Frequency | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mold steel | |

| Length measurement | Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power(kw) | 15 KW (Depend on final design) | |

| Hydraulic station power | 5.5K W (Depend on final design) | |

| Total power(kw) | 20.5KW | |

| Uncoiler’s loading capacity | Max. Capacity: 3000kgs | |

1. Designed by 15 years experienced R&D members with lifetime seivices.

Parameters

| Technical parameters | ||

| Item | Specification | |

| Raw Material | Type | galvanized coils |

| Thickness(mm) | 1.5-3.0 | |

| Yield strength(mpa) | 235-345 | |

| Roller material | Cr12 mould steel | |

| Hardness of rollers | HRC58-60 | |

| Shaft for rollers | 82mm Solid shaft, processed with cylindrical grinder | |

| Forming speed(m/min) | About 10-15 | |

| Speed adjusting mode | Misubishi frequency transformer | |

| Roller drive | Decelerating motor + Chain drive | |

| Cutting mode | Hydraulic cutting | |

| Cutter material | Cr12 mould steel | |

| Length measurement | Nemicon Encoder | |

| Control mode | Mitsubishi PLC | |

| Operating mode | Button + Mitsubishi Touch screen | |

| Main motor power(kw) | About15KW | |

| Total power(kw) | About 20.5KW | |

| Process flow | Decoiler — Feeding & Guiding — Roll forming—Hydraulic Cutting – product to run out table | |

| Components of machine | ||

| Decoiler (manual decoiler and hydraulic decoiler for option) | 1set | |

| Feeding & guiding device | 1set | |

| Main roll forming machine | 1set | |

| Hydraulic cutting system | 1set | |

| Mitsubishi Controlling system | 1set | |

| Run out table | 1set | |