AUTO Cut To Length Line Machine

Steel CZ Purlin Roll Forming Machine Price

April 4, 2023

Auxiliary Equipment

April 4, 2023Hydraulic Cutting Slitting Machine & Cut to Length Line Roll Forming Machine

Product Description

Summary

1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 17+ years experience;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 20m/min;

5). Very easy to install and operate the roll forming machine.

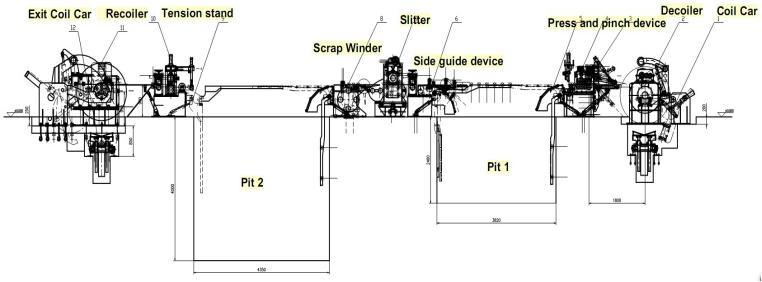

Machine working flow:

Machine Technical Specifications:

About raw material and product for roll forming machine

| Material&product | Feeding width | according to profile |

| Effective width | according to profile | |

| Raw material | PPGI | |

| Thickness | 0.3-2mm | |

| Yield strength | 280-350 MPA |

What the main machine will be?→as below

| NO. | Name | unit | parameters |

| 1 | Control model | Frequency conversion control | |

| 2 | Materials | Hot rolled steel | |

| 3 | Thickness | mm | 0.3-2mm |

| 4 | Width | mm | 1250 |

| 5 | Coil I.D. | mm | 508(Customized) |

| 6 | Coil O.D. | mm | 1600 |

| 7 | Weight | T | 15 |

| 8 | Slitting blade shaft | mm | Φ220 |

| 9 | Blade specification | mm | Φ340×Φ200×15 |

| 10 | Material of blade | 6CrW2Si | |

| 11 | Blade hardness | HRC58°-60° | |

| 11 | Line speed | m/min | 0-30m/min |

| 12 | Power of slitter | KW | 45 |

| 13 | Power of recoiler | KW | 55 |

| 14 | Quantity of strips (Max) | Pieces | 25 pieces(0.3-1mm) 8-10 pieces(1-2mm), |

| 15 | Width tolerance | ≤±0.05 mm/2M | |

| 16 | The direction of whole line | from right to left, the operate table faces the machines | |

| 17 | Power | 380V/3Ph/50Hz(Customized) | |

| 18 | Operation people | 1 technician and 2 general worker | |

| 19 | Color | Green ( Customized) |

Detailed Photos

This is the 10T hydraulic decoiler with car,the function is supporting the steel coils and do the uncoiling

The car can move levelly and vertically, which is convenient for putting the steel coils into the de-coiler.

It is driven vertically byφ160 hydraulic cylinder with four guide pillars.

It is made by 5 leveling rollers , drive device , 2 pinch roller and frame. Every roller is the main driving rollers.

The gap between rollers can be adjusted manually to make sure the leveling quality.

Drive model: all the rollers and gear box drives by 11 KW motor

Power part: This is composed of power-stand, 15KW direct current motor, gear distributing case, coupler, spindle, connecting-cover, etc.

Host machine: This is composed of bottom-stand, fixed bracket, big slide, knife pivot(φ200mm, 2pcs), movable bracket, slide, the front and back adjustable device of bracket, knife pivot lifting and pressing down adjustment device, accompany of blade, separating cover, rubber band and 10 blades with the machine

It change the blades through moving out the bracket hydraulically and is very convenient and fast

Designed with the seamless expand and shrink structure and hydraulic clip-mouth so that when the heads feed into the clip-mouth, it will close automatically and start winding.