Auxiliary Equipment

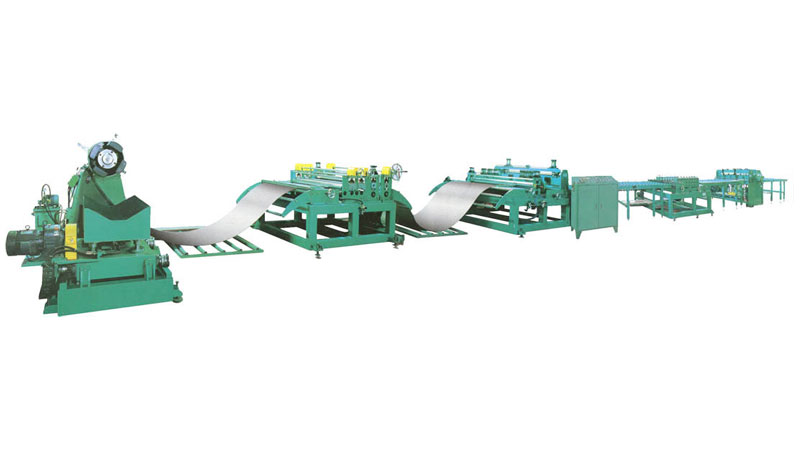

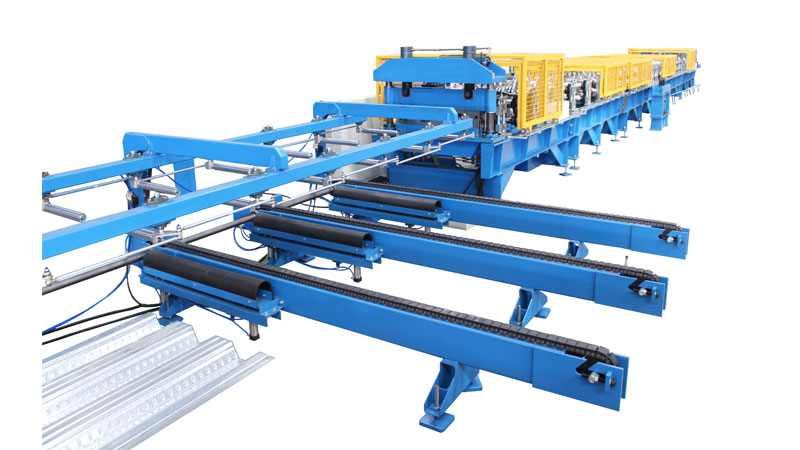

AUTO Cut To Length Line Machine

April 4, 2023

C/U/Z/M Purlin Roll Forming Machine

April 4, 2023Auxiliary Equipment Display

Decoilers

Decoilers Crimping & Curving Machine

Crimping & Curving Machine Coil Upender

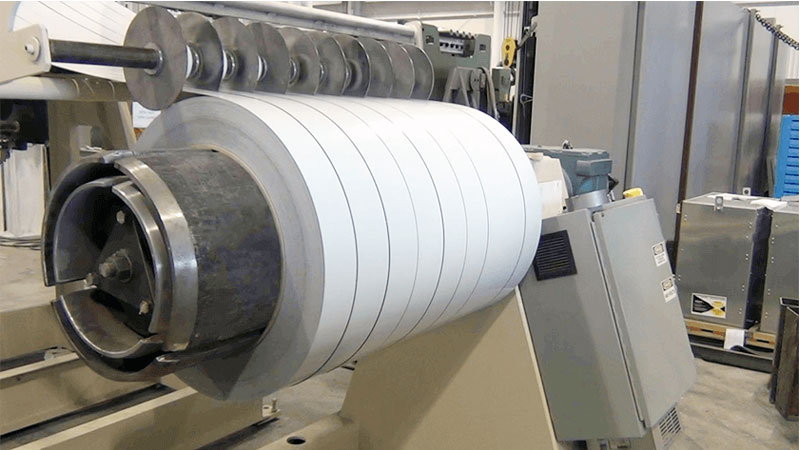

Coil Upender Slitting Line

Slitting Line Cut To Length Line

Cut To Length Line Vertical Stacker

Vertical Stacker Hydraulic Shearing Machine

Hydraulic Shearing Machine Metal Cutting Machines

Metal Cutting Machines Simple Cut to Length and Slitting Machine

Simple Cut to Length and Slitting Machine Coil Embossing Machine

Coil Embossing Machine Recoilers

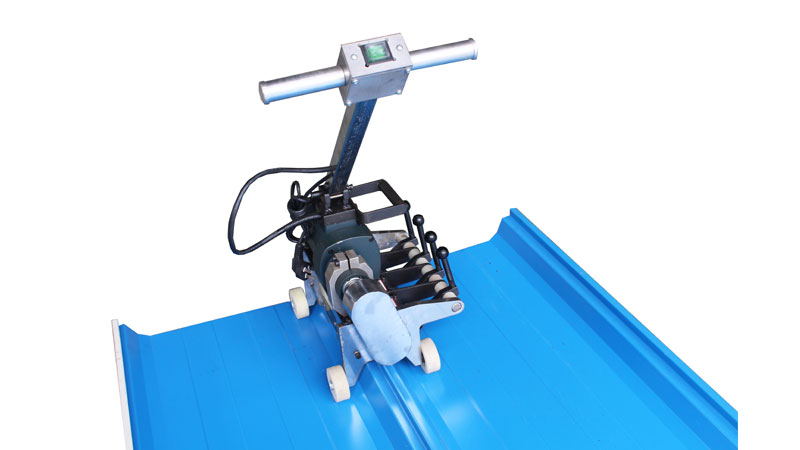

Recoilers Automatic Roof Seaming Machine

Automatic Roof Seaming Machine Vertical Cage Accumulator

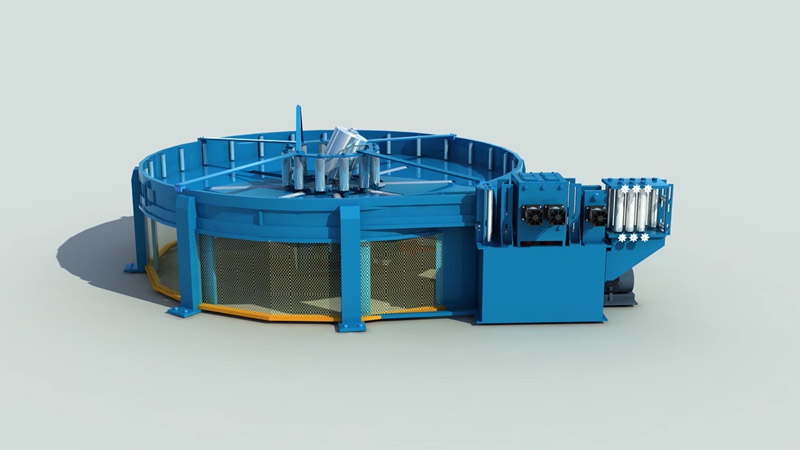

Vertical Cage Accumulator Horizontal Accumulator

Horizontal Accumulator Large Horizontal Spiral Accumulator

Large Horizontal Spiral Accumulator Logo Printing Machine

Logo Printing Machine CNC Folder

CNC Folder Sheet Stacker

Sheet Stacker Flying Saw

Flying Saw Hydraulic Automatic Shear and Butt-Welding Machine

Hydraulic Automatic Shear and Butt-Welding Machine

Auxiliary Equipments Mill Line

Tube/Pipe Mill Line is used for producing tubes of various sizes and profiles. The composition of equipment is from decoiler to run-out table. The main machine includes forming, welding, sizing and straightening device. Auxiliary Equipments includes decoilers, shearing and butt-welding machines, accumulator, guiding device, straightening machine, cold cutting saw(flying saw), run-out table and packing machine.

- Decoiler

Double-side 360º rotary decoiler insures steel coil feeding alternatively and make steel strip going into accumulator freely

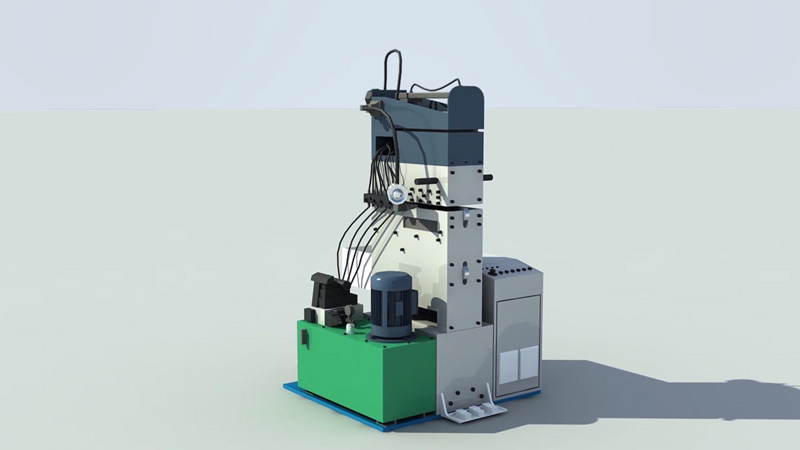

- Shearing and Butt-welding machine

Shearing and butt-welding machine is used to parallelly cut the tail of the strip which has just gone into the accumulator, and the head of the strip coming out from decoiler, and then weld them together.

- Accumulator

There are two types of accumulator: horizontal accumulator and cage accumulator. Accumulator can receive strip steel discontinuously from decoiler and provide the steel strip to forming device at the same time. Accumulator stores large amount of strip and leaves enough time for the shear and butt-welding machines to shear and weld the ends of strips.

- Straightening Machine

Straightening machine is a finishing equipment for the tube/pipe mill line, which straighten the steel pipe/tube to eliminate the bending and stress after the steel pipe/tube forming and welding.

- Cold cutting saw(flying saw)

Cold cutting saw is the mechanical equipment specially for continuously production, auto fixed ruler cutting steel pipes, which is one of the auxiliary equipment for continuously weld pipe production line.

- Run-out table and packing machine

Run-out table and packing machine is a packaging equipment designed especially for continuously weld pipe production line, which can automatic pack the tubes or pipes into hexagonal or square shapes, and then automatic bundling, sloping and weighting.